|

Design and production of machines: design and construction of machines for the production of footwear and automotive filters.

Realization of compact machines and multi-units modular machinery for the production of filters of any shape and dimension.

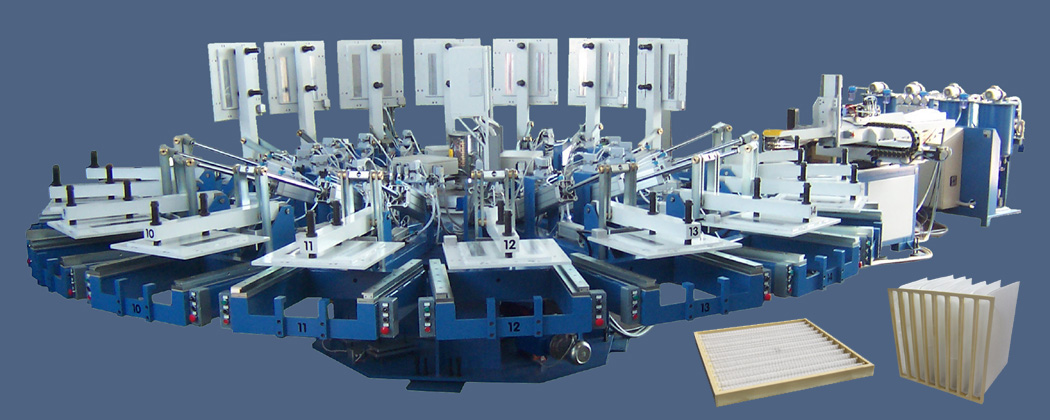

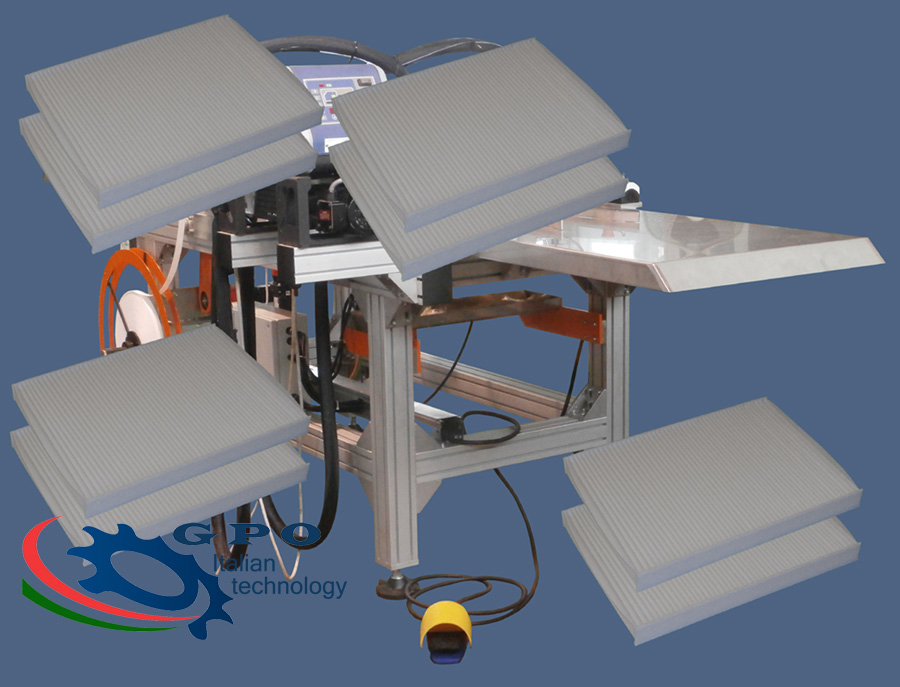

Below, a machine with a 18 mould-holders rotary table mod. MFT 818 with 3 electronic axes casting unit, for the production of rigid PU frames for both technical filters and pocket filters, and soft PU gaskets for special filters.

MFT 818 machine schedule

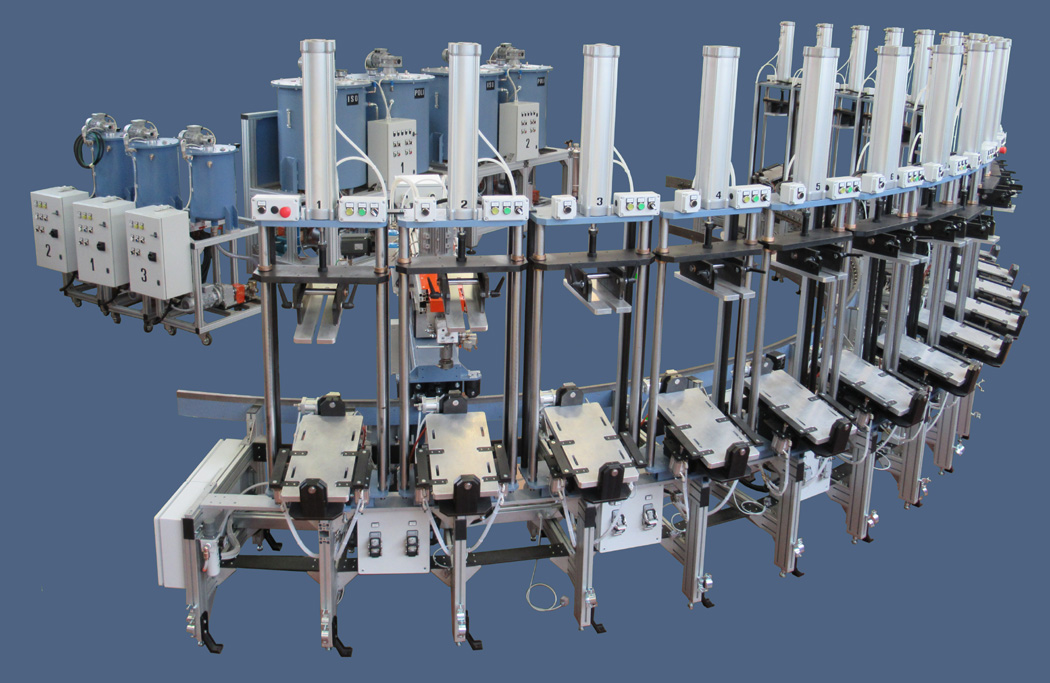

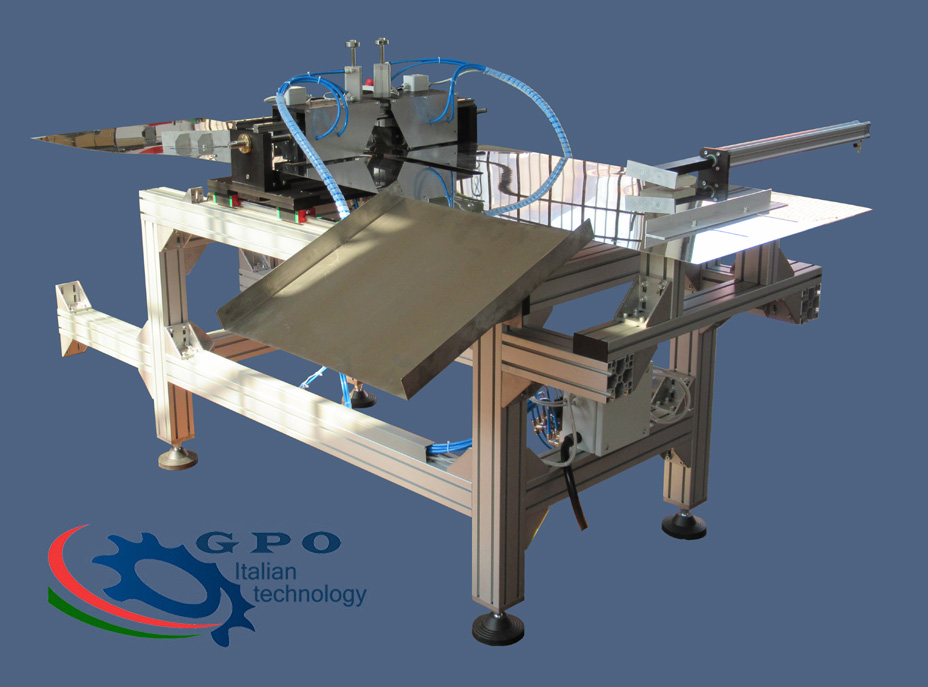

Below, a machine with 18 static mould-holders and an automatic shifting casting unit, casting with an electronic pantograph for the production of PU soles mod. MVA 223 18.

MVA 223 18 machine schedule

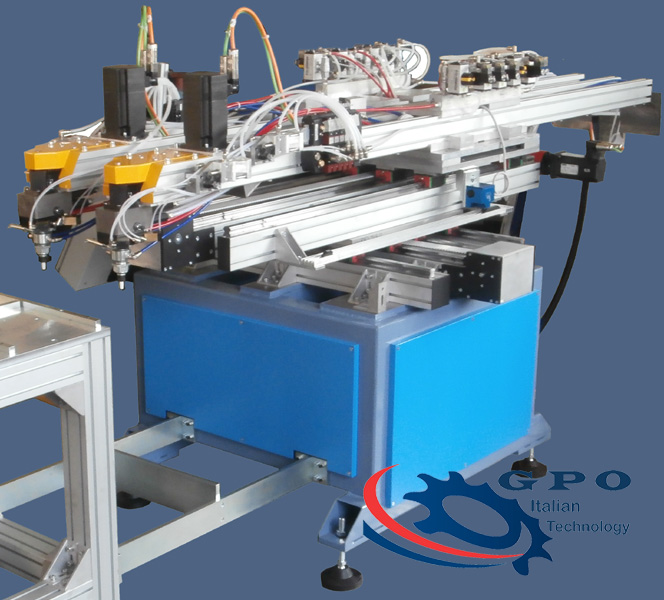

Below on the left, the GPO-Italy Machine mod. MCH 100, with casting head insertable in a fixed support or drivable by hand, for the production of automotive filters with polyurethane gaskets.

MCH 100 machine schedule

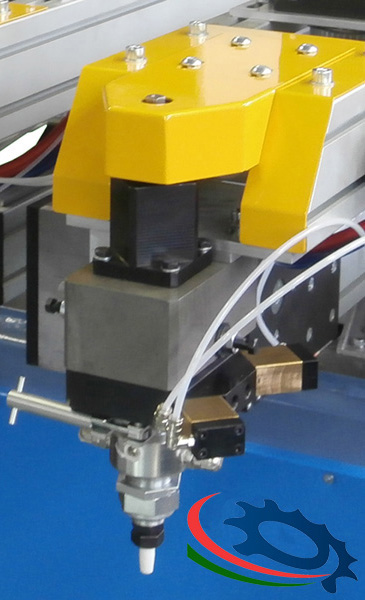

Below on the right, a GPO-Italy casting head suitable for the machine model MCH 100.

Casting head drivable manually mod. 11 PT

Below in the left, A 2 components and 2 coloring pastes GPO-Italy casting head for the production of polyurethane gaskets for filters. Coloring of the material takes place directly in the casting head.

Features of PU casting and injection heads

Below on the right, a GPO-Italy casting unit with 2 axes supporting 2 casting heads for the production of polyurethane gaskets for filters.

Below on the left, a 2-tanks components dosing unit for the production of polyurethane gaskets for filters. GPO-Italy dosing units can support multiple tanks, depending on the number of components (isocyanates and polyols) expected.

Below on the right, a GPO-Italy electrical-electronic cabinet which is present in all GPO-Italy modular machinery supporting different devices

and equipment.

Below, a color paste dispenser, optional device matchable with other GPO-Italy modular machines.

Below, the semiautomatic machine for the side band application for cabin filters production mod. MSB 820.

MSB 820 machine schedule

Below, the additional module for cabin filters cutting and unloads, for machine mod. MSB 820 described above. It is so obtained the machine mod. MSB 821.

MSB 821 machine schedule.

Below, the automatic machine with side band application module and filters cutting module for cabin filters production mod. MSB 830

MSB 830 machine schedule

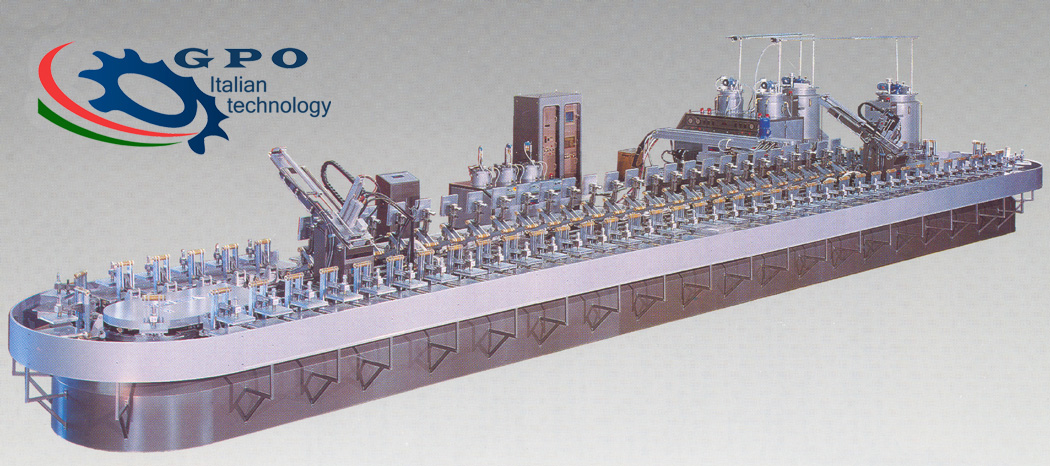

Below, an automatic conveyor with 48 mould holders stations for the production of footwears.

For examples of filters and other items realized with GPO-Italy machines, visit our

products gallery page.

GPO-Italy has the technological capability to design and build machines, including special ones, for the production of filters, technical articles and footwear.

-

Modular machines for the casting of polyurethane materials for automotive, heavy duty and industrial filters:

- Modular machines for the production of panel filters of various sizes and any flat shape, consisting of: a multi-stations rotary table with mould holders (from 14 to 24 stations), 2 or 3 axis casting unit for polyurethane, dosing unit, electrical cabinet with setting-and-control PC; on request, extraction systems and paste dispensers for coloring the material directly into the casting head. The casting head can be with components recirculation, with direct casting or a self-cleaning one without the use of solvents;

- Modular machines for the production of pocket and frame filters, having the same characteristics as those mentioned above; the rotary table typically owns 18 stations;

- Modular machines for the production of circular filters of various sizes, consisting of a multistation rotary table with revolving rotary plates (4 to 24), polyurethane dosing-and-casting unit, electrical cabinet with setting and control PC; this is a cheaper solution than modular machines for the production of filters of any flat shape, but limits production to circular filters only;

- Modular machines for the production of industrial filters of various sizes and any flat shape, formed by a large pantograph, casting head mounted on mobile cart, dosing unit, electrical cabinet with setup and control PC.

-

Compact machines for casting polyurethane materials for automotive, ecological and industrial filters:

- Compact machines for the production of round filters with polyurethane gasket;

- Compact machines with head drivable also manually for the production of small or very small series of filters with polyurethane gasket, with rapid variation of parameters and consequent change of production without the need of washing the casting head;

- Compact machines for casting epoxy resin for the production of small round filters; the machine is available with a single rotating plate or with a built-in small rotary table that supports 4 or 8 plates;

- Compact machines with a movable arm for casting polyurethane by guiding the head manually;

- Agitators for polyurethane components in tanks.

-

Other filter production machines:

- Machines with one or more stations for gluing the edges of the filtering media to produce filters with circular shape;

- Semiautomatic machines with manual loading and unloading for the angular cutting of the filtering media blocks.

-

Machines for the production of cabin filters:

- Automatic machines for the application of the side bands and the cut-in-measure of the filter, starting from the filtering media with pre-incised folds

- Semiautomatic machines for the application of the side band to the filter media packs.

-

Special machines for the production of footwear with soles in polyurethane:

- Automatic machines for the production of footwear with soles in polyurethane, consisting of support unit for 6 or 12 mould-holders arranged in an arc of a circle, 2-axis polyurethane casting unit automatically translating between the various stations, dosing unit, electric cabinet with setup-and-control PC.

|