|

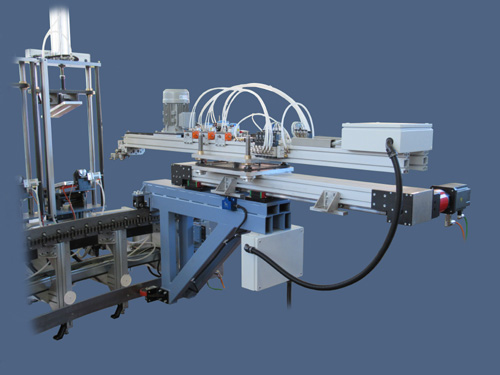

MVA 223 18 machine schedule:

- Production: polyurethane soles.

- Peculiarities:

- Production of soles with special plastic film with vacuum system.

- Static mould holders machine with vertical closure.

- Casting head: mounted on a 2-axis electronic casting unit automatically translating from mould to mould.

- Indicative dimensions: 12,000 mm width, 8,000 mm depth, 2750 mm height.

- Basic machine composition:

- N° 1 component dosing unit with 270 l tanks for isocyanate and polyol.

- N° 18 static mould-holders arranged in a quadrant.

- N° 1 casting unit translating from mould to mould.

- N° 1 electrical/electronic cabinet.

- Optional customization add-ons:

- N° 1 dosing unit for each of the additional polyurethane components required.

- N° 1 color dosing unit with 50 l tank and insertion of the coloring paste directly in the casting head for each of the required colors (maximum 3 units for each machine).

- Infrared lamps: they are used to heat and liquify the adhesive applied on the rubber soles inserted in the mould. The system, with chose of the customer, can include a lamp for each mould or a single lamp translating from mould to mould on which the polyurethane mixture is subsequently casted.

|