|

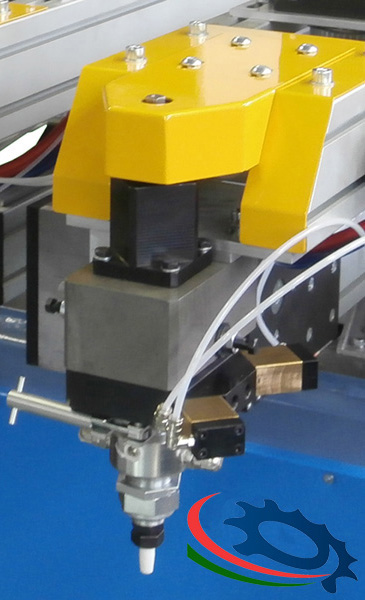

Casting and injection heads built from GPO-Italy are built in hardened steel and are placed at the top of the polyurethane technology.

The forty-year experience of GPO-Italy designers enables the design and construction of heads to suit many different production requirements.

Casting of traditional polyurethanes, thixotropic materials, polyurethane glues, epoxy resins.

Casting of traditional polyurethanes, thixotropic materials, polyurethane glues, epoxy resins.

Use of dynamic mixing screws or static mixers.

Heads suitable to be assembled with multiple stations machines or single station machines.

Presence of automatisms for the selection of different materials such as 2 or more polyols, 2 or more isocyanates, selectable by programs.

For the internal cleaning, possibility of usage of different solvents, water or to automatically alternate the selection of solvents and water depending

from the needs.

The usage of self-cleaning casting heads moreover completely removes the need of usage of washing liquids.

Heads for the casting of different quantity of material, from micro castings to high flow castings.

The maintenance is more easy and fast, compared to other casting heads on the market.

The drop at the end of the casting is drastically reduced/eliminated through the application of internal solutions, also after long periods of usage of the casting head.

Direct colouring of the materials into the mixing chamber, using one or more different colours, till 4, selectable by programs.

GPO-Italy casting heads can be mounted on already existing machines to improve performances, production rate and durability.

|