|

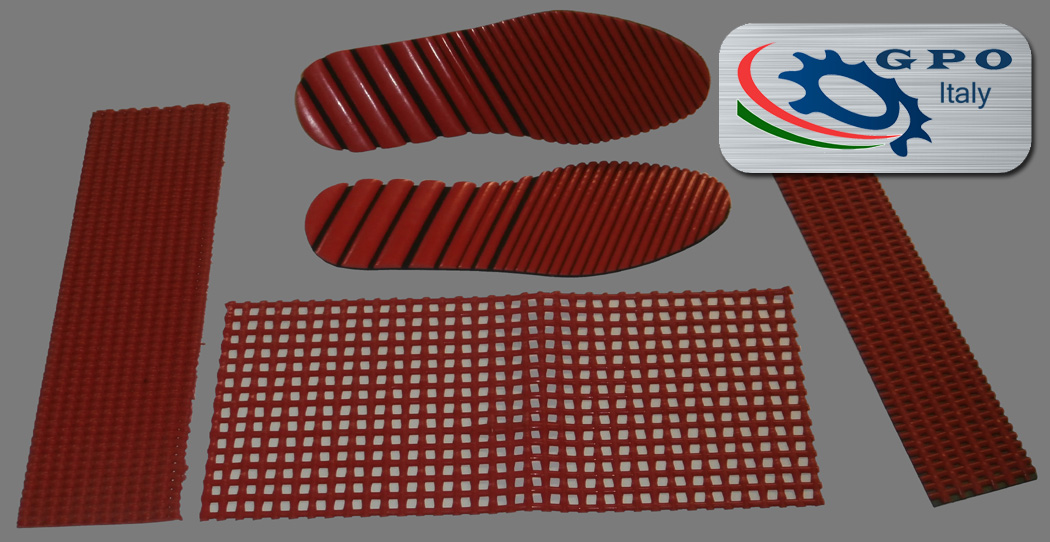

With GPO-Italy machines see the production of @ new generation of insoles covered by international patent.

Produced exclusively with GPO-Italy machines. Tested in University of Pavia, with the certification of CIMAC (Italian center of footwear materials

application), the main characteristics are: an average replacement of the air inside the shoe of 7 cubic centimeters, shock absorption, 100% elastic memory,

self-forming anatomy, permanent scent, washable also in washing-machine.

|